Ever wondered what it really takes to turn a rough idea for a custom medical tape into something that’s actually stacked up in warehouses, ready for clinics and hospitals? If you’re kicking around a new product – maybe a gentler tape for sensitive skin or one that holds up during surgeries – the whole thing can feel a bit overwhelming at first. That’s where a solid partner like MediTapes comes in. We’ve been doing this for years, guiding folks through the medical tape OEM process from those early sketches all the way to cranking out thousands of rolls.

The medical adhesive tapes market is growing pretty quick these days. According to The Business Research Company, it hit about $8.97 billion in 2024 and is expected to climb to $9.85 billion in 2025. That’s because more people need better wound care, wearable devices, and stuff for surgeries. We see that demand firsthand at MediTapes – clients coming to us wanting tapes that stick well but don’t irritate skin, or ones that work with sensors for monitoring patients.

In this guide, I’ll walk you through how we handle the medical tape OEM process here. No fluff, just the real steps we’ve refined over tons of projects. Whether you’re a startup or an established brand, understanding this helps you see how we cooperate and what our production capabilities look like.

Breathable Perforated Adhesive Tape – Skin Color & Latex Free

Our skin-colored perforated adhesive plaster offers superior breathability and comfort. Latex-free formula minimizes allergic reactions, making it perfect for sensitive skin. This porous medical tape tears easily by hand. A trusted choice for clinics and first aid kits worldwide.

What OEM Really Means for Medical Tapes

OEM stands for Original Equipment Manufacturer, but in our world, it basically means we make your custom medical tape under your brand. You bring the idea or specs, we handle the medical tape prototyping, manufacturing process, and scaling up through contract manufacturing.

Why go this route? It lets you focus on selling and innovating without building your own factory. We’ve got the cleanrooms, machines, and know-how already set up. Plus, medical tapes have to meet strict rules – like FDA classification as Class I devices for most adhesive tapes and bandages, and biocompatibility testing under ISO 10993 standards. We take care of that compliance stuff so you don’t have to start from scratch.

Contract manufacturing with us means flexible volumes too. We can start small for testing and ramp up to millions of units when you’re ready.

Kicking Off with Medical Tape Prototyping

The fun part starts here – medical tape prototyping. This is where your concept gets real.

You reach out with your needs: maybe a silicone-based tape for neonates, or an acrylic one for sports applications. We chat about materials – paper, fabric, foam, plastic films – and adhesives that are skin-friendly.

Then our team mocks up initial samples. We use small-scale coating lines to apply adhesive to backing materials, cut them into rolls or sheets, and send you prototypes pretty quick, often in 2-4 weeks depending on complexity.

We’ve had clients tweak things a bunch during this phase. One anonymous project was for a transparent film tape used in IV securement. They wanted it breathable but strong. We iterated three times on adhesive strength before nailing it – now it’s in regular production for them.

Testing Your Prototype Like It Matters

Prototypes aren’t just for looks. We run real tests:

- Adhesion tests on skin models (peel strength, tack)

- Biocompatibility per ISO 10993 – cytotoxicity, irritation, sensitization

- Shear and tensile strength

- Breathability and moisture vapor transmission

If it’s for longer wear, we check for residue or skin reactions. All this follows FDA guidelines for medical adhesive tapes.

This phase catches issues early, saving headaches later. We’ve seen prototypes fail initial stickiness in humid conditions, so we adjusted the formula and turned it around.

Perforated Non-woven Silicone Tape – Easy Tear & High Breathability

This perforated Non-woven Silicone Tape allows for easy tearing without scissors, streamlining clinical workflows. The porous structure ensures high breathability, keeping the wound site dry. Using premium silicone gel technology, it offers reliable fixation for IV lines and gauze with zero skin irritation.

Transitioning to the Full Manufacturing Process

Once prototyping is solid, we move into the manufacturing process. This is where things get structured.

We develop a detailed production plan: material sourcing, coating widths, slitting sizes, packaging options.

Our facility has multiple coating lines that can handle widths up to 1600mm, speeds over 100 meters per minute. That means serious capacity for mass runs.

Key steps in the manufacturing process:

| Stage | What Happens | Why It Matters | Typical Timeline |

|---|---|---|---|

| Material Prep | Backing and adhesive raw materials arrive, tested for quality | Ensures consistency from batch to batch | 1-2 weeks |

| Coating & Drying | Adhesive applied to backing, dried in controlled ovens | Controls thickness and uniformity | Ongoing in runs |

| Slitting & Rewinding | Cut into customer-specified widths and roll lengths | Matches your exact needs | Part of production run |

| Packaging | Spools, sheets, or die-cuts, labeled and boxed | Ready for sterile or non-sterile distribution | Final step |

| Quality Checks | In-line and final inspections | Catches any defects early | Throughout |

We use medical-grade materials only, and everything happens in ISO-certified clean environments to avoid contamination.

For contract manufacturing, we can also add printing (like your logo) or special liners.

Blue Silicone Gel Tape with Perforation for Secure Medical Fixation

Our Blue Silicone Gel Tape features easy-tear perforation for quick medical application. This soft silicone gel tape provides secure fixation for IV lines and dressings while protecting the stratum corneum. Waterproof and flexible, it conforms to body contours perfectly for maximum patient comfort.

Scaling Up to Mass Production

Here’s where production capabilities shine. Once the manufacturing process is validated, mass production kicks in.

We run validation batches – usually 3 consecutive lots that meet specs – to prove consistency. This is crucial for regulatory files if you need them.

Our lines can output hundreds of thousands of square meters per month. For a recent client (keeping it anonymous), we scaled a wound dressing tape from 5,000 units in pilot to over 500,000 monthly within six months.

Challenges in scaling? Maintaining adhesive performance at higher speeds, or managing heat during drying for sensitive formulas. We’ve got tricks for that – optimized oven zones, precise tension control.

Throughout, quality control is nonstop: inline cameras, automated measurements, and lab tests on samples.

Quality and Compliance Built In

No one wants tapes that fail in real use. That’s why we lean heavy on standards.

All our medical tapes go through biocompatibility evaluation based on ISO 10993-1. For skin contact devices, that includes tests for irritation and sensitization.

We’re registered with FDA for medical device manufacturing, and follow good manufacturing practices.

We’ve helped clients prepare 510(k) submissions when needed (though most basic tapes are exempt as Class I).

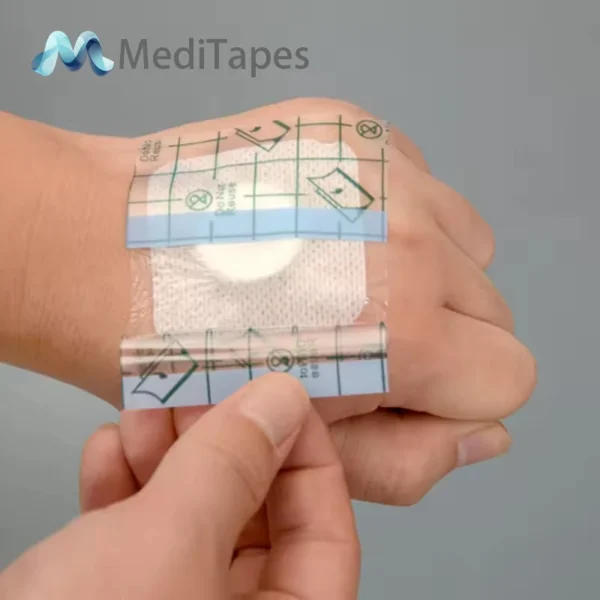

Hypoallergenic PU Film Dressing Roll Wholesale – Bulk Wound Care

Sourcing reliable supplies? Our Hypoallergenic PU Film Dressing Roll is available for Bulk Wound Care orders. Featuring a grid backing for precise cutting, this transparent roll minimizes allergic reactions. It is a cost-effective, premium choice for securing medical devices and primary dressings in high-volume environments.

Real-World Applications and Success Stories

Medical tapes show up everywhere:

- Wound dressings and bandages

- Surgical drapes and incise films

- Electrode fixation for ECG monitoring

- Wearable sensors and patches

- Ostomy securement

- Sports strapping and kinesiology

One project we loved: a startup needed a hypoallergenic tape for pediatric use. Through medical tape prototyping, we developed a soft cloth backing with gentle adhesive. After testing showed zero irritation in trials, we moved to contract manufacturing. Now it’s used in hospitals across several countries.

Another was a waterproof transparent tape for outdoor medical kits. We tweaked the adhesive for wet adhesion, scaled the manufacturing process, and they’re shipping globally.

These stories show how flexible our setup is – from niche low-volume to high-output runs.

Why Partner with MediTapes for Your Medical Tape OEM Process

We’ve got the experience – decades combined in the team, hundreds of custom projects done.

Capacity-wise, multiple lines mean we handle surges without delays.

Location helps too: efficient supply chain for raw materials from trusted suppliers.

And we’re easy to work with. No huge minimums forcing you into overstock, quick responses, transparent pricing.

If you’re curious about costs or timelines for your idea, just drop us a line.

Ready to Get Your Medical Tape Project Rolling?

By now you probably have a clearer picture of the medical tape OEM process – from those first prototypes through the manufacturing process and into full-scale contract manufacturing.

It’s not as complicated as it seems when you’ve got a partner who’s done it before.

If this sounds like what you need, reach out to the team at MediTapes. We’d love to hear about your idea and see how we can help bring it to life.

Head over to our contact page or email info@meditapes.com for a quote or just to chat details. No pressure – we can start with a quick call to scope things out.

Looking forward to possibly working together!

Medical Non-woven Tape Manufacturer | Breathable Surgical Paper Tape

Our Medical Non-woven Tape offers superior breathability and strong adhesion for wound care. This microporous surgical paper tape is hypoallergenic and gentle on sensitive skin. Choose our CE-certified medical non-woven tape for reliable dressing fixation and bulk wholesale supply.

Frequently Asked Questions About Medical Tape OEM Process

How long does the entire medical tape OEM process take from idea to mass production?

It varies, but typically 3-6 months for straightforward projects. Medical tape prototyping might take 4-8 weeks, validation another 4-6, then mass production ramps up quick after that. Complex formulas or regulatory needs can stretch it to 9-12 months.

What minimum order quantities do you have for contract manufacturing?

We keep it flexible – pilot runs can be as low as a few thousand units to test the market. For full mass production, we scale based on your forecast, no crazy high MOQs that lock you in.

Do you handle regulatory compliance like FDA or ISO for custom tapes?

Yes, we manufacture under FDA registration and ISO 13485 quality systems. We provide documentation for biocompatibility (ISO 10993) and can support your filings. Most standard medical tapes fall under Class I, so often no premarket notification needed.

Can you help with custom features like colored tapes or special adhesives?

Absolutely – that’s a big part of what we do in medical tape prototyping. We’ve developed antimicrobial coatings, high-tack for devices, low-trauma removal, you name it.

What’s the advantage of contract manufacturing over building my own production?

Saves you massive upfront costs on equipment and facilities, plus you get our expertise right away. Faster time to market, scalable without risk, and we handle the day-to-day manufacturing headaches.