It’s not the most glamorous part of elite sports. But I’ve spent enough time on the slopes and in the manufacturing lab to tell you this: a fifty-cent blister can ruin a fifty-thousand-dollar training season.

If you are sourcing products for winter sports teams, clinics, or retail distribution, you already know the stakes. The market is flooded with cheap bandages that peel off the second they touch a sweaty sock. That’s garbage. Today, I want to get into the weeds of why hydrocolloid blister plasters are the only serious option for winter friction injuries and what you, as a buyer, need to look for when vetting a blister plaster manufacturer.

The Physics of the Ski Boot: Why We Get Blistered

To understand why standard plasters fail, we have to look at the environment inside a ski boot. It is a biomechanical nightmare.

You have a rigid outer shell and a soft liner, but the forces are massive. When a skier carves a turn, the normal force (N) increases significantly. We can look at the basic friction formula:

Ff = mu * N

Where Ff is the Force of Friction, mu is the coefficient of friction, and N is the Normal Force (pressure).

Here is the problem. In winter sports, mu (the coefficient) is unstable.

- Cold: Makes the skin dry and brittle initially.

- Heat/Sweat: As the athlete works, the boot becomes a sauna. Moisture increases the coefficient of friction dramatically. Wet skin blisters faster than dry skin.

Most generic adhesive bandages fail because their adhesive chemistry cannot handle the shift from -10°C external temp to 30°C internal boot temp combined with high moisture. This is where high-quality hydrocolloid blister plasters come in. They aren’t just stickers; they are active wound management systems.

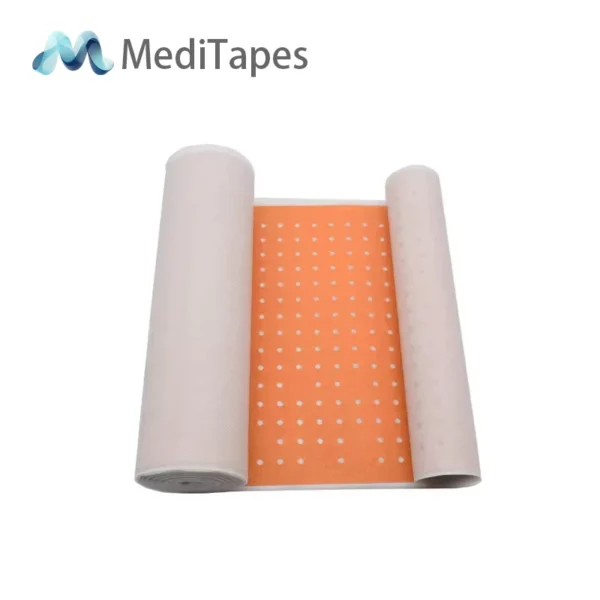

Breathable Perforated Adhesive Tape – Skin Color & Latex Free

Our skin-colored perforated adhesive plaster offers superior breathability and comfort. Latex-free formula minimizes allergic reactions, making it perfect for sensitive skin. This porous medical tape tears easily by hand. A trusted choice for clinics and first aid kits worldwide.

Hydrocolloid Tech: More Than Just a Sticker

I’ve had arguments with procurement managers who think “a bandage is a bandage.” They are wrong.

A hydrocolloid dressing is composed of gel-forming agents (like sodium carboxymethylcellulose) sitting in an adhesive compound, laminated onto a flexible outer layer (usually polyurethane). When the plaster absorbs exudate (fluid) from the blister, it forms a soft gel.

This does two things for the athlete:

- Cushioning: It physically increases the distance between the boot and the raw nerve endings.

- Moist Healing: It prevents the formation of a hard scab, which is actually detrimental to continuing sport because scabs crack and bleed under movement.

Comparison: Standard vs. Hydrocolloid

I made this table to break down why hydrocolloid blister plasters are superior for your B2B clients who demand performance.

| Feature | Standard Gauze Bandage | Professional Hydrocolloid |

|---|---|---|

| Adhesion Mechanism | Simple acrylic glue | Hydrocolloid matrix + border adhesive |

| Waterproof? | Rarely | Yes (Semi-permeable) |

| Cushioning | Minimal (flattened easily) | High (maintains gel structure) |

| Friction Reduction | Low (fabric catches on socks) | High (smooth polyurethane film) |

| Wear Time | Hours | 3 to 7 Days |

For a hydrocolloid dressing wholesale buyer, the “Wear Time” is the selling point. Athletes don’t want to change dressings mid-race.

Sourcing Matters: Not All Hydrocolloids Are Created Equal

Okay, here is where I get a bit technical. As a blister plaster manufacturer, we see a lot of variation in quality.

If you are importing these for your brand, you need to ask your supplier about the MVTR (Moisture Vapor Transmission Rate).

If the MVTR is too low, the skin macerates (turns white and mushy) because the sweat can’t escape. If it’s too high, the wound dries out.

At MediTapes, we aim for that “Goldilocks” zone. We’ve tweaked our formulation to ensure that our hydrocolloid blister plasters stick even when the skin is already slightly damp. This is crucial for winter sports care, where application often happens in a locker room or on the side of a snowy hill.

Another thing? The edges. Cheap plasters have square edges. These catch on wool ski socks immediately. You want a manufacturer that produces tapered edges. It costs more to manufacture because the die-cutting process is more complex, but it prevents the plaster from rolling up.

A Quick Note on Preventative Taping

While hydrocolloids are for when the damage is done (or about to happen), prevention is key. Many elite skiers use rigid tape under their socks before they even step outside.

If your catalog is missing this, check out our Perforated Adhesive Plaster. It’s breathable and provides that first layer of defense. I usually recommend distributors carry both: the preventative tape and the reactive hydrocolloid blister plasters.

Heavy Duty Perforated Adhesive Plaster for Sports & Injury Support

Designed for durability, this heavy-duty perforated adhesive plaster provides rigid support for sports injuries and joint stabilization. High tensile strength keeps dressings in place during activity. The perforated design allows sweat evaporation. Essential for sports medicine suppliers.

Case Study: The Alpine Training Camp

I can’t name the specific team due to NDAs, but a couple of years back, we supplied a European alpine ski team during their summer training in South America.

They were having a nightmare season with boot fit issues. New sponsor, new boots, lots of blisters. They were using generic pharmacy-grade plasters. The issue? The plasters would bunch up inside the boot, creating more pressure points.

The Solution:

We switched them to our heavy-duty hydrocolloid blister plasters with a specific 0.8mm thickness and a high-tack border.

The Result:

- Downtime Reduction: Athletes missing training sessions due to foot pain dropped by roughly 40%.

- Healing Time: Existing blisters healed while they continued to ski because the gel pad distributed the force (F) effectively.

This isn’t magic. It’s just good materials science. When you buy hydrocolloid dressing wholesale, you aren’t buying a commodity; you are buying uptime for athletes.

What B2B Buyers Need to Ask Manufacturers

If you are looking for a blister plaster manufacturer, don’t just look at the price per unit. That’s a trap. A cheap plaster that falls off costs you a customer forever.

Here is my checklist for you:

- Adhesive Stability: Ask for stability test data at low temperatures. Will the glue freeze and crack at -5°C?

- Sterilization Method: Gamma or Ethylene Oxide? (Gamma is generally preferred for integrity, though both work).

- Customization: Can they do custom shapes? Heel shapes are different from toe shapes. A good supplier offers variety.

We handle this daily at MediTapes. We know that winter sports care is a niche that demands high specs. If you are tired of inconsistent quality, you should probably contact us to discuss your specs.

Application Tips for the End User

Since you are likely selling to coaches or retailers, pass this advice along. It adds value to your product.

- Warm it up: Before applying hydrocolloid blister plasters, rub the plaster between hands for 30 seconds. The adhesive is heat-activated.

- Clean the area: Grease is the enemy. No lotions. Alcohol wipes are best.

- Don’t pop it: If the blister is intact, put the plaster right over it. The hydrocolloid will cushion it.

It sounds simple, but you’d be surprised how many people get this wrong and then blame the product.

The Future of Blister Prevention

We are seeing some interesting trends in winter sports care. There is a move towards thinner but denser hydrocolloids that fit better in tighter, custom-molded ski boots.

Also, sustainability is popping up. Clients are asking about the biodegradability of the polyurethane film. It’s a challenge for the industry because biodegradable materials often degrade too fast in wet conditions (like a sweaty boot), but we are working on it.

Why Choose MediTapes?

Look, I could sit here and write marketing fluff all day, but the reality is simple. We specialize in medical tapes and dressings. We understand the chemistry of adhesion.

When you are looking for hydrocolloid blister plasters or looking to stock up on hydrocolloid dressing wholesale, you need a partner who understands the difference between “sticky” and “functional.”

We have the production capacity to handle large OEM orders, but we are agile enough to care about the specific formulation you need for your market. Whether it’s for extreme winter sports or everyday hiking, the principle remains the same: protect the skin, keep it moist, keep it moving.

Don’t let your customers down with inferior products. If you are ready to upgrade your supply chain, shoot us an email at info@meditapes.com or visit our contact page. Let’s get your athletes back on the slopes.

Wholesale Perforated Adhesive Plaster Rolls – Bulk Medical Supply

Looking for bulk perforated adhesive plaster? We supply high-quality, cost-effective plaster rolls for global distributors. Features consistent unwind tension and reliable adhesion. Our perforated medical plaster meets international standards. Contact us for OEM packaging and competitive pricing.

FAQ: Frequently Asked Questions

Q: How long can hydrocolloid blister plasters stay on during sports?

A: In high-friction environments like ski boots, a high-quality hydrocolloid plaster should last 2 to 3 days. For less intense activities, they can stay on for up to 7 days until they naturally detach.

Q: Can I buy hydrocolloid dressing wholesale with my own brand logo?

A: Yes, absolutely. As a dedicated blister plaster manufacturer, MediTapes offers OEM/ODM services. We can customize the packaging, the shape of the plasters, and the thickness to suit your brand’s specific needs in the winter sports care market.

Q: Why do hydrocolloid plasters turn white after use?

A: That is actually a good sign! The white bubble indicates that the hydrocolloid material has absorbed fluid (exudate) from the blister and turned into a gel. This gel cushions the wound and speeds up healing. If it turns white, it’s working.

Ready to secure the best protection for your clients?

Don’t wait for the winter season to peak. High-performance athletes need high-performance gear now.

- Identify your volume needs.

- Request a sample of our premium hydrocolloids.

- Contact our team today.